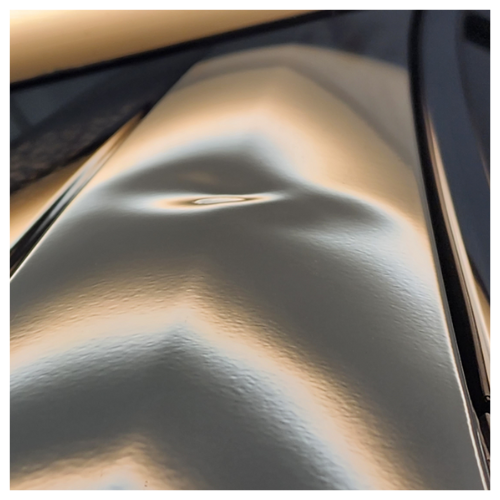

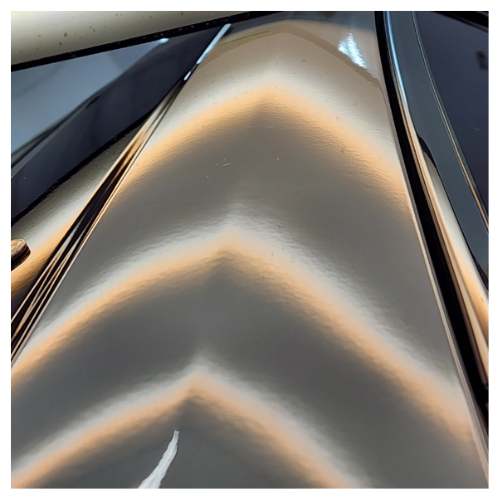

Paintless Dent Repair

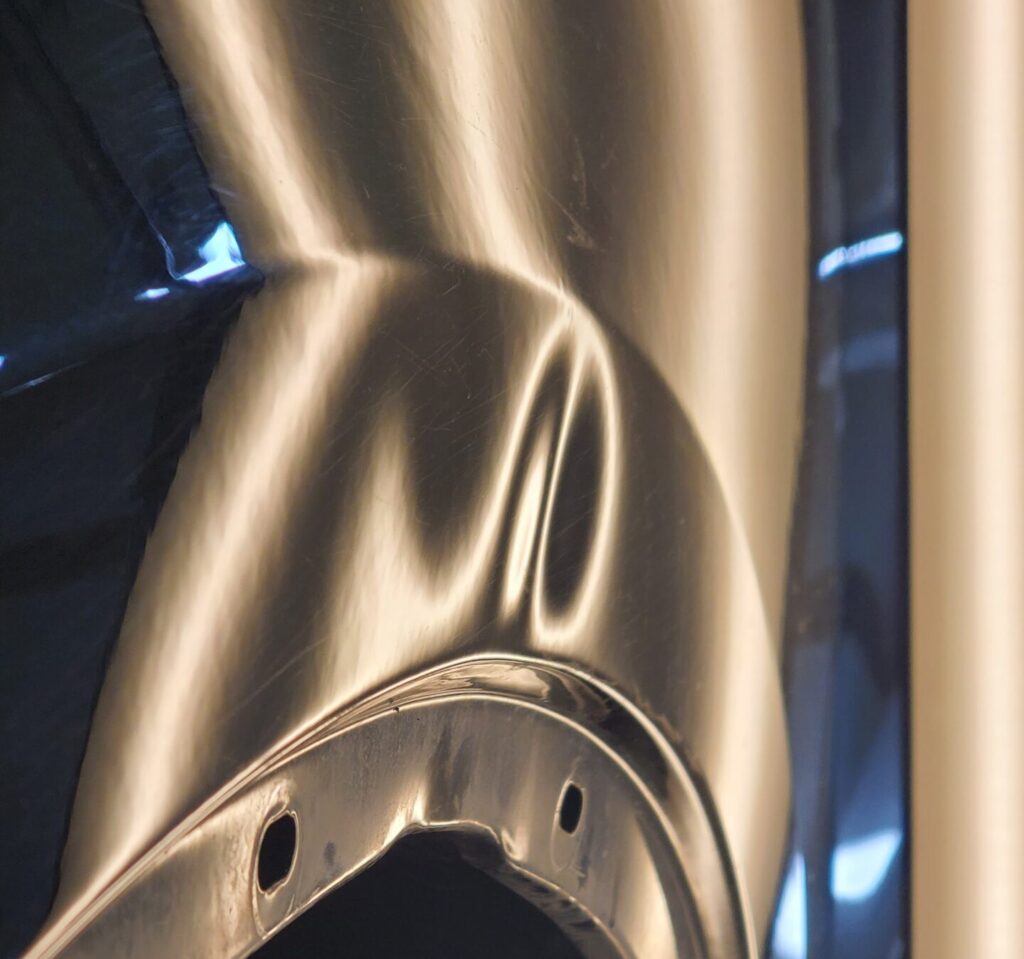

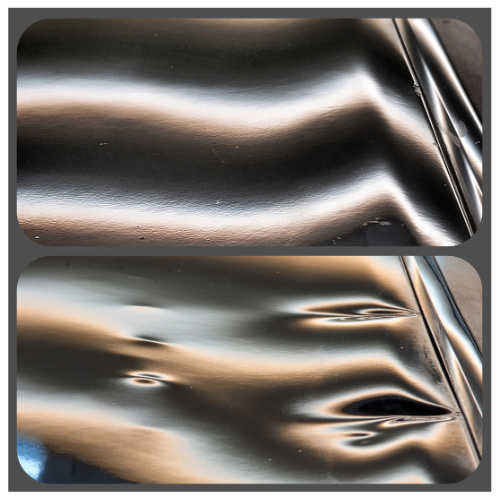

Paintless dent repair (or paintless dent removal) is the process of removing dents and dings from automotive panels by using one, or a mixture of, the following techniques.

Massage. Paintless dent repair technicians have hundreds of specialized tools that assist in “seeing ” damage (an industry specific light) and then massaging the dent or ding from the back side of the panel with PDR rods and hand tools made for the industry.

Glue Pulling. Technicians have four tools they primarily use for this technique. A mini lifter, a slide hammer, glue tabs and auto industry specific hot glue.

Knock Down. Technicians use two tools for this technique. A small hammer and “tapdown” tool. The tech uses the hammer and taps down on the tapdown when his/her pushing has created whats know as a “highspot”.

Find more information below on each area!

- Home

- Single Service

Paintless dent repair is really an art form.

More about Paintless Dent Repair:

- Paintless dent repair is known as "PDR".

- PDR has been in use since the 70s.

- PDR is preferred by insurance for hail damage repair.

- PDR is cost effective and efficient.

- Most PDR techs receive specialized school training.

- PDR doesn't require bondo or paint.

History of Paintless Dent Repair:

“Paintless dent removal was started by Frank T. Sargent in 1931, when he wrote a groundbreaking work “The Key To Metal Bumping”. This book describes the tools of paintless dent repair, how to use them, and even gives illustrations on how one might predict the metal to move.

Almost 30 years later Oskar Flaig made the first public display on record, in February 1960 during the “International Motor Sports Show” in New York City, USA.

Oskar Flaig was an ordinary member of staff at Mercedes-Benz. His job was to take care of the paintwork of all the show cars presented at trade fairs. Damage, scratches on the paintwork and small dents, produced by the public during the day, needed to be re-painted at night, so the vehicles would be in perfect condition the next day.

At the trade fair in New York City, Oskar Flaig used a hammer handle to push out a small dent, so he would need to apply less filler before painting. Nevertheless, the result already looked perfect after pushing. After the show, Flaig returned home to Germany and started developing techniques and tools to repair dents.

He was eventually promoted to foreman at the Mercedes Sindelfingen plant where he was known as the “golden tinsmith” and started PDR training programs at all branch plants. These techniques were used in Germany for a long time before finally being promoted as a successful way to repair dents in the United States in 1979-1983 when Juergen Holzer moved from Germany to Minneapolis, Minnesota and started Dent Kraft (the first recorded business in the United States use paintless dent repair).”

Training in Paintless Dent Repair:

There are multiple options available to those who are interested in starting a career in paintless dent repair:

- Go to a training school.

- DING KING is one. The owner, Todd Sudeck is a great businessman and has been around for a long time.

- Paintless Dent Repair Training Academy. They have been around since 1993.

- Many more.

- Get Private instruction/Mentorship.

- Tom Price with PDR LEGENDS. We’ve known Tom for several years, from meeting him at MTE (Mobile Trade Expo) to working with him when he managed a shop near our own, we have nothing but good things to say about him.

- Ask us about training. WIth over 30 years experience and multiple successful techs trained, we can help you.

- DIY/Figure it out on your own.

- Not many will find success this way, but there are those who do.

Cost of Paintless Dent Repair:

With any of the following, please consider the following:

- Price listed if for the FIRST dent of the job.

- Discounts are given following the first dent.

- Free dentwork is available with jobs that have multiple dents. See our home page for the special.

-

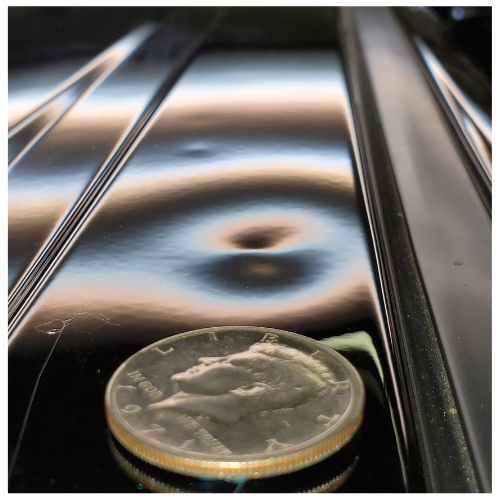

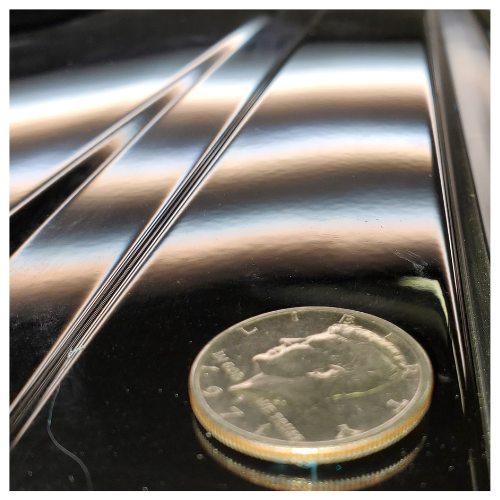

Dime Sized Ding $75

Any single ding, up to the size of a dime.

-

Quarter Sized Dent $125

Any dent, larger than a dime, but smaller than a quarter.

-

50 Cent Piece Sized Dent $195

Any dent, larger than a quarter, but smaller than a 50 cent piece.

-

Larger Dent $195+

Any dent larger than a 50 cent piece is priced starting at $195.00. Add $25 per inch of damage beyond baseline.

-

Crease $125+

Any dent that is creased is priced per inch, starting at $125.00. Add $50.00 per inch after baseline.